OGS Metal Services

For more than 60 years, OGS Industries in Akron has been known for exceeding customer expectations with high-speed metal services and U.S.A-made metal stampings, metal fabrication, and Swiss and CNC machining across numerous industries including aerospace, defense, industrial, medical, recreational, and transportation. As your one-stop-shop for metal forming and machining, we are committed to limiting errors and reducing costs. We prioritize continuous improvement and are always improving our lead time and procedures with our AS9100, ISO 9001, ISO 14001, IATF 16949, and ITAR certifications.

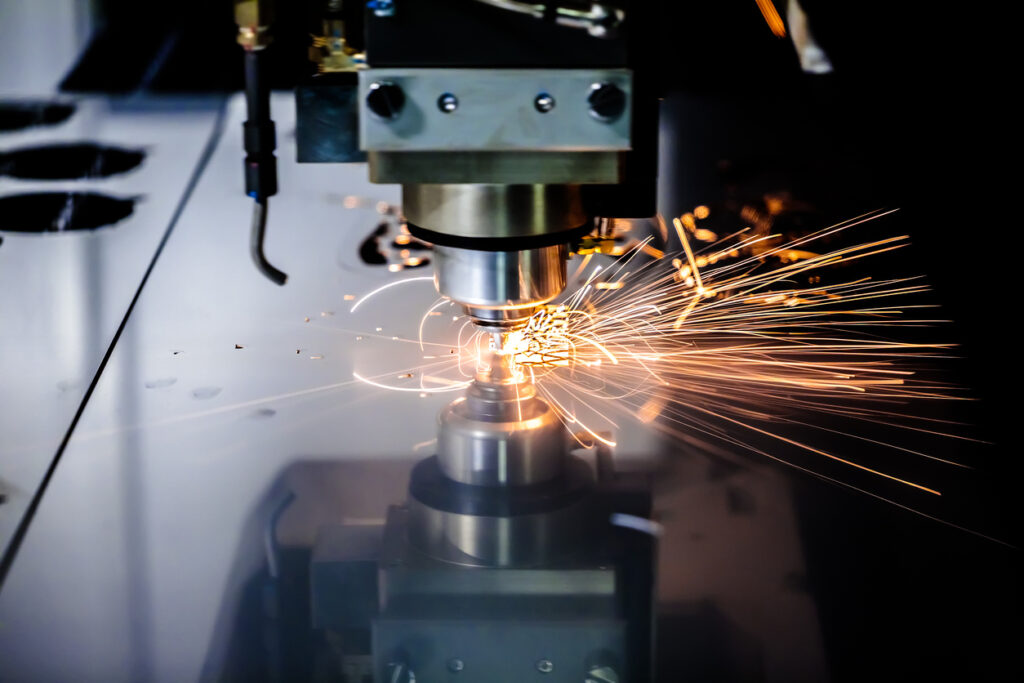

Using the latest technology, our metal services produce everything from higher volumes of sheet metal fabrication to lower volumes of complex CNC components, and everything in between, including precision metal stamping, shims, metallic gaskets, small screw machine parts, and installation hand tools. Our expertise transforms standard metal with stamping under 500 tons, laser cutting under 3/4 inch, punching, forming, welding, milling, centerless grinding, and CNC and Swiss machining. The tooling we produce is the most cost-effective for runs over 10,000 pieces per month.

Why OGS?

At OGS, our customer-lead, quality-driven metal services and certifications allow us to consistently meet customer cost expectations and product specifications. Learn more about what makes us different, simplify decisions with recent industry trends insights, and put over 60 years of manufacturing experience to work by requesting a quote.